This specialist article discusses insulating glass production and quality control methods for double and triple glazed insulating glass units (IGUs). A key question in IGU manufacturing is simple but critical:

Why break the insulating glass unit for gas analysis if non-destructive methods are available?

“Keeping pace with high performing insulating glass products is a struggle for quality control, especially when it comes to insulating gas retention. Glazing products today have higher and higher performance needs, and the requirements for better products are growing steadily.”

Energy Performance and Gas Retention in Insulating Glass Units

Today’s glass products carry a wide range of elements enhancing their properties. One main property is the energy efficiency in both heated and cooled buildings. Modern insulating glass units rely on several methods to enhance energy performance. These include:

- Low-E coatings

- Multiple glass panes

- A medium between the panes

The medium can be:

- Air

- Vacuum

- An insulating gas, typically argon or krypton

These insulating gases are applied to the cavity either during the manufacturing process at gas press station, or manually to the ready-made units. The challenges are confirming the correct filling degree and ensuring that the initial gas concentration will remain inside the insulating glass unit (IGU) in other words long-term gas retention inside the IGU.

Gas leakage is usually caused by imperfect sealing and is not visible. Because insulating glass and window suppliers (and other industries that use IGUs) may carry product liability for years after delivery, confirming gas concentration before shipping is essential.

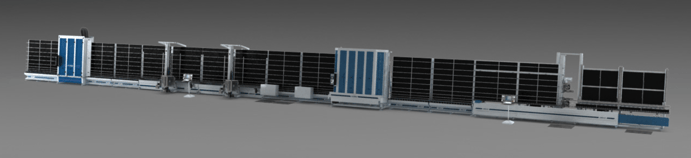

IG line with argon press (courtesy of Forel)

Why Argon Gas Retention Matters

Insulating gases consist of small molecules and are naturally prone to leakage over time. For this reason, manufacturers typically aim for very high initial gas concentrations, often 95% or more, directly after filling.

Although standards vary by region, best practices are well established. One example is the European standard EN-1279 which defines acceptable gas loss over time.

Under EN 1279:

- Maximum allowed gas leakage is approximately 1% per year

- After 10 years, the IGU must still retain at least 81.39% of the original insulating gas

This makes gas retention a long-term performance issue, not just a production parameter.

Invasive vs. Non-Invasive Gas Analysis Methods

Invasive Gas Measurement

Invasive gas analysis methods require penetrating the IGU seal to extract a gas sample. These methods are:

- Affordable

- Robust

- Generally accurate

However, they damage the IGU, which means:

- The unit cannot be delivered to the customer

- Retesting is not possible

For many manufacturers, this limits invasive methods to sampling or laboratory use.

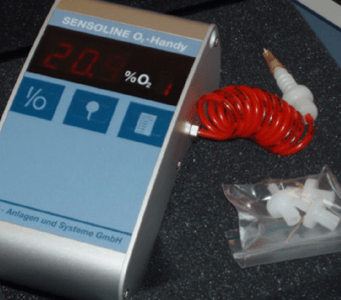

Sensoline argon gas testing device

Non-Invasive Gas Measurement

The non-invasive gas analysis allows the gas concentration to be measured without breaking the insulating glass unit. This makes it possible to verify gas fill levels while keeping the IGU intact and suitable for delivery or further testing.

One widely used non-invasive method is spark-based gas measurement, where a controlled spark is ignited through the glass. By analyzing the color and emission spectrum of the ionized gas, the argon concentration inside the cavity can be calculated automatically.

Spark-based measurement is:

- Fast

- Accurate

- Well suited for routine quality control

It is commonly used for double glazed units, where measurement can be performed from the monolithic glass side on non-coated surfaces. Because the IGU remains undamaged, measurements can be repeated as often as required by the quality system or end-user.

The main limitation of spark-based technology is that it is best suited for:

- Double glazed units

- Structures with no more than one Low-E coating

non-invasive Sparklike Handheld device measuring ionized gas emission spectrum

Measuring Complex IGU Structures

Advances in non-invasive measurement technology have expanded gas analysis to more complex insulating glass structures. Laser-based gas analysis enables measurement through multiple coatings and laminated glass without damaging the unit.

This makes it possible to test:

- Energy-efficient triple glazed unit. Read more in our Are Triple Glazed IGUs Necessary to Obtain Energy Efficient Windows? article.

- IGUs with multiple Low-E coatings

- Laminated and advanced glazing structures

Laser-based technology determines gas concentration by measuring the oxygen level inside the cavity. From this data, the percentage of insulating gas, most commonly argon or krypton, can be calculated with high accuracy.

How Sparklike Laser™ devices measure insulating glass units without having to break the glass

Gas Retention Testing in Production Quality Control

Non-invasive gas measurement plays a central role in modern IGU production quality control. Both spark-based and laser-based technologies are used, depending on the IGU structure and production requirements.

Non-invasive gas measurement systems can be:

- Used as handheld devices for spot checks and routine verification

- Applied as portable solutions near the production line

- Integrated directly into the IG production line and connected to production control software

Measuring gas content on produced units supports:

- Reliable and repeatable quality assurance

- Early detection of sealing or filling issues

- Documentation of gas retention performance over time

In today’s IGU manufacturing environment, quality control is not only about eliminating rejects. Verified gas fill levels and proven gas retention have become a key factor in product reliability, compliance, and customer confidence.

Sparklike Devices for Non-Invasive Gas Analysis of IGUs

Sparklike offers non-invasive gas measurement solutions for different insulating glass structures and quality control needs:

Sparklike Handheld™

Spark-based non-invasive device for measuring argon and krypton gas concentration in double glazed insulating glass units.

Sparklike Laser Portable™

Laser-based non-invasive device for measuring gas concentration in double and triple glazed insulating glass units, including structures with coatings and lamination.

Sparklike Laser Integrated™

Automated laser-based insulating gas measurement system designed for integration into the IG production line. Suitable for double and triple glazed insulating glass units with coatings and lamination.