BUILDING ENERGY CONSUMPTION

It has been calculated that in North America and Europe, the buildings consume a staggering 40% of the primary energy consumption (Cao, Dai & Liu, 2016). However, this figure can significantly be reduced if the buildings are purposefully designed, constructed and used. Furthermore, a report released by IEA (International Energy Agency) clearly stated that from the overall energy of office buildings, 20% is being consumed on lighting, 16% to heating and 14% to cooling. (Ürge-Vorsatz, 2012.) Hence, it is important to talk about repair construction and structural energy efficiency to enhance the existing surroundings.

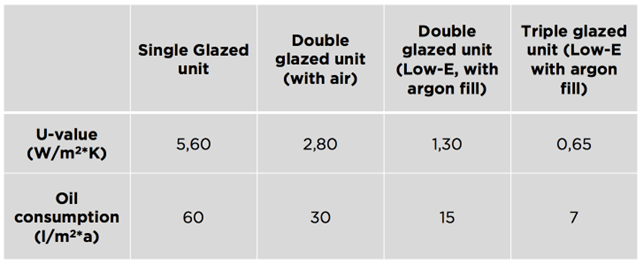

Typically, about 15–20% of building wall surface is windows. At the same time, it has been estimated that 25% of building’s energy consumption could be reduced, if the windows were argon filled double glazed units. On the other hand, in office buildings where the glass surfaces are generally much greater, argon filled triple glazed units can help to obtain even up to 50% energy saving compared to the use of air-filled windows. Therefore, it has become clear that windows are not merely an aesthetic element but play a primordial role when considering buildings’ maintenance costs. (Lange, 2012.) To further explore the subject of buildings’ maintenance costs, a well-known supplier of essential products for the global construction industry, Akzo Noble interpreted glass and glazing units’ energy consumption (U-value) by converting it to oil consumption. The table number 1 shown below represents the main results for single glazed as well as double glazed and triple glazed insulating glass units.

As can be observed from the above table, cost – here oil consumption – can radically be reduced by using argon filled insulating glass units. Most prominent increase in oil consumption can be detected between the single glazed unit and the argon filled Low-E coated and triple glazed unit, where oil consumption increases by staggering 757%

It is interesting to compare the figures from the above table with the building component specific U-value reference values. In other words, the requirements related to building’s repair and modification work aimed to improve energy efficiency often suggest minimum levels for improving energy efficiency. However, these figures are quite often country specific, the following values are from Finland. The building component specific U-value reference value set for the construction of new building’s windows and doors is 1,0 W/m²K. (Ojanen et al. 2017, 8.) In most cases, it is important to work towards solutions that help to surpass the minimum requirement. When considering these requirement, one good goal for repair construction is the U-value reference value set for new constructions: 0,7 W/m²K. (Lylykangas et al. 2016, 2.)

When considering the above-listed facts on building energy consumption, it is understandable that there is an ever-growing interest towards energy efficiency. However, the general conversation on energy efficiency quickly turns into discussions on energy production and the capability and efficiency of energy transfer. However, if the insulation in buildings has not been installed properly, the energy cost reductions and climate benefits gained in the beginning of the production chain, can quickly be gone with the wind.

To that end, the next chapter discusses different ways how energy efficiency can also be achieved during the later stages of the production chain. In other words, the following chapter lists leading causes for repair constructions and how structural energy efficiency can be achieved.

LEADING CAUSES FOR REPAIR CONSTRUCTION AND ENSURING THE STRUCTURAL ENERGY EFFICIENCY

Buildings are being repaired more than before since, for one reason or another; they fail to satisfy the inhabitant’s or owner’s expectations. The causes for that can be divided into three different categories (Stolt, 2015):

- change in the building’s function

- wearing and aging of buildings and their components

- buildings and their components becoming damaged.

When a change in the building’s function occurs, it can lead to a need for a repair construction. This, on the other hand, is often closely related to the building inhabitant’s or owner’s acknowledged and experienced needs. Therefore, it goes without saying that the change in the building’s function is strongly time and trend related. (Stolt, 2015.)

The wearing and aging of buildings and their components refers to the process where the usability is significantly reduced. Wearing takes place when buildings or their parts are subjected to normal use. Aging, on the other hand, can be caused by the combined effects of internal chemical processes and some external stress factors. However, the reduction in building usability or utility caused by wearing and aging of buildings and their components, can be examined from various points of view, such as goals set for buildings safety, economic efficiency or living comfort. It is important to notice that the property owner is responsible for eliminating any factors that may pose safety or health issues. This means that the property owner needs to ensure that the premises meet the minimum requirements. (Stolt, 2015).

Repair construction can often be initiated when wanting to improve the building’s indoor air quality and energy efficiency. Improving the structures’ thermal insulation, is an easy way to enhance building’s energy efficiency and living comfort. At the same time, indoor air thermal comfort or ambient conditions improves, when the draft caused by cold surfaces and uncontrolled air leakage can be reduced. (Ojanen et al. 2017, 8.) In addition to the indoor air temperature, residential building’s living comfort can be affected by the surface temperature of the surrounding constructions and the degree of relative air humidity, (Lylykangas et al. 2016, 2.)

Furthermore, living comfort and energy efficiency can significantly be improved with structural energy efficiency. The passive energy saving systems, methods and technologies that help to achieve these goals are, for example, adequate heat insulating of structures and the use of high-quality insulating glass units. Passive energy saving and structural energy efficiency can also be achieved by reducing the need for indoor air cooling when using sun shadings and window coatings. These solutions require no additional maintenance after the initial installation has been done, while significantly improving buildings indoor air quality and reducing heat loss. When considering the improvement of the whole building’s energy efficiency through repair construction, it is mainly based on properly heating, cooling and insulated airtight structures. (Ojanen et al. 2017, 8.)

As was mentioned in the beginning of this article, 25% of building’s energy consumption could be reduced, if the windows were argon filled double glazed units. On the other hand, in office buildings argon filled triple glazed units can help to obtain even up to 50% energy saving compared to the use of air-filled windows. (Lange, 2012.)

Therefore, it can be concluded that when considering repair constructed buildings and structural energy efficiency, the structures’ proper heat insulation is a cost-effective way to reduce need for heating. Finally, properly heat insulated buildings and high-quality insulating glass units can significantly reduce energy consumption and guarantee thermal comfort. (Lylykangas et al. 2016, 2.)

REFERENCES:

Cao, Xiaodong, Dai, Xilei, Liu, Junjie: Building energy-consumption status worldwide and the state-of-the-art technologies for zero-energy buildings during the past decade, Energy and Buildings, 2016, s. 1

Lange, Dieter: Energy saving without noble gas filling?, Akzo Nobel, 2012, s. 1

Lylykangas, Kimmo, Andersson, Albert, Kiuru, Jari, Nieminen, Jyri & Päätalo, Juha: Rakenteellinen energiatehokkuus, opas. RTT eristeteollisuus ja ympäristöministeri 2016, ss. 2–3

Ojanen, Tuomo, Nykänen, Esa, Hemmilä, Kari: Rakenteellinen energiatehokkuus korjausrakentamisessa, opas. ymp.rist.ministeri., Rakennustuoteteollisuus RTT ry ja Puutuoteteollisuus ry, 2017, s. 8

Stolt, Toni: Korjausrakentamisen tietomallintaminen ja Tekla Structures -komponentit, Metropolia ammattikorkeakoulu, 2015, s. 8-9

Ürge-Vorsatz, Diana: Global Energy Assessment, Chapter 10 – Energy End-Use: Buildings, 2012, s. 660