The following specialist article discusses the technology behind Sparklike Laser™ product line. This article was written based on an interview with Mr. Kai Niiranen, the R&D Engineer at Sparklike Oy, the person who has developed the analysis technology that allow the measurement of insulating gas fill without breaking the insulating glass unit or without having any extra components inside. Mr. Niiranen has held the position as Sparklike’s R&D Engineer since 2010.

Kai Niiranen holds a master’s degree in Optical Technology and a bachelor’s degree in Automation and Electronics. His past job experiences include working as Production Engineer in brain navigation and stimulation manufacturing company Nexstim and as Testing Engineer in mammography manufacturing company Planmed. They are both high technology companies in Finland with worldwide business operations.

DEVELOPMENT OF SPARKLIKE LASER™ DEVICES

Mr. Niiranen developed the Sparklike Laser™ product line to correspond to the changes in the insulating glass industry, where an ever-increasing number of insulating glass units are manufactured with coating on both sides. Thus, a new technology was needed to enable non-invasive gas fill concentration measurement through coating and laminated glasses.

laminated glasses

Bearing that in mind, the initial development process was started by first, searching and comparing a plethora of non-destructive measurement techniques used in gas detection. After which, it was time to rule out techniques which were not capable of making a measurement through glass; clear, coated or laminated. During the 3rd phase of the development process, Mr. Niiranen started to compare the remaining options by using criteria such as possible achievable accuracy, price, size, and the power needed in terms of input and output. From there he narrowed down the different options to one choice, which was to utilize the laser based TDLAS technology.

TDLAS technology in IGU quality control

All devices within the Sparklike Laser™ product line, are based on TDLAS (Tuneable Diode Laser Absorption Spectroscopy). By using this technology, the device measures oxygen and from there, the amount of argon, krypton, or other insulating gas, can be calculated. When measuring the insulating gas fill concentration inside an IG unit, the laser beam goes through the first pane and is reflected to the detector from the first surface of the second pane. In addition, with a triple insulating glass unit, the laser beam goes through two panes and is reflected from the third pane. Finally, to get the focused laser beam to the correct measuring point, the IG dimensions are first scanned. This is done by moving the focused laser beam through the IG and collecting the reflected signal to obtain accurate dimensions of the IG. This, in return, enables the calculation of the gas concentration(s).

As Sparklike Laser™ product line was developed to correspond to the changes in the insulating glass industry, Mr. Niiranen first developed the Sparklike Laser Standard™ device which is an offline solution for test laboratories and desktop use. This device was later integrated into a robust case with wheels and a battery for mobility in factories and building sites, and labelled Sparklike Laser Portable™. The third and latest addition to the product line is Sparklike Laser Online™ (Sparklike Laser Integrated™), which is a custom-made solution that is integrated to an insulating glass line for automated inspection. To understand better read why there’s no need to break the insulating glass unit in order to conduct insulating glass unit’s argon fill analysis.

SPARKLIKE LASER™ MEASUREMENT THROUGH DIFFERENT IGU LAYERS

Different IGU coatings have different transmissions. Opposite for transmission, is reflection. Simple equation for reflection is R = 1 – T, where T is transmission. When measuring an IG unit with a low transmission on the first pane and high transmission (low reflection) on the surface where the beam is reflected to the detector, the measurement signal is small, and the device accuracy can be reduced. On the other hand, when the situation is opposite, the reflected signal as the device accuracy, is high.

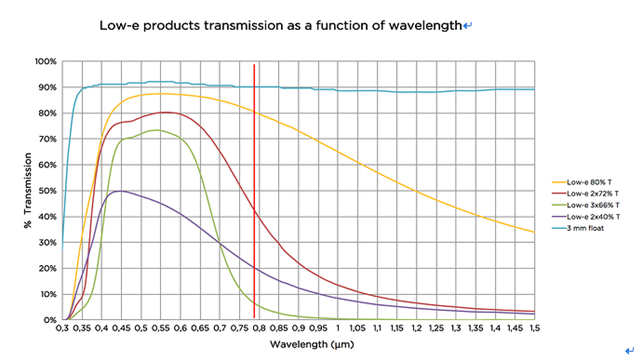

The following figure shows different low-e product transmissions versus wavelength, where the vertical red line indicates the laser (wavelength = 760 nm) used in the Sparklike Laser™ devices.

As we can see from the above figure, different coatings have different transmission spectrum and the transmission depends on the wavelength.