Summary: Step-by-Step: Insulating Glass Manufacturing Process Explained

- Process overview: IGU production involves multiple precise steps—material preparation, cutting, edging, washing, spacer assembly, gas filling, sealing, and final quality control.

- Role of machinery: Automated systems ensure consistency in spacing, sealing, and alignment, improving efficiency and reducing errors.

- Gas filling importance: Filling argon or krypton is critical for thermal performance. Accurate gas concentration directly impacts energy efficiency.

- Add-ons: Special coatings, extra glass layers, or advanced gas fills enhance IGU properties such as insulation, sound reduction, and UV protection.

- Quality control with Sparklike: Non-invasive Sparklike devices verify gas fill levels without damaging the IGU, ensuring compliance with standards and long-term performance.

The manufacturing process of insulating glass units (IGUs) is a precise and carefully controlled operation that combines engineered materials, automated machinery, and strict quality control. Each stage of production directly influences the thermal, acoustic, and durability performance of the final insulating glass unit.

This article provides a step-by-step overview of the insulating glass manufacturing process, highlighting where precision matters most and why quality control, like insulating gas measurement, is important in ensuring reliable IGU performance.

Read also our previous article Optimizing Quality Control Process of Insulating Glass Units.

Detailing the Step-by-Step Process of Insulating Glass Production

Material Preparation

The manufacturing process begins with the preparation of raw materials. High-quality glass sheets are selected based on the intended application, and coatings or films — such as low-emissivity layers — are applied when required. The choice of glass type and coatings directly affects the thermal and acoustic properties of the finished IGU.

Glass Cutting

Precision is essential during glass cutting. Glass sheets are cut to exact dimensions using advanced cutting machinery. Accurate cutting ensures proper alignment during assembly and prevents dimensional issues that could compromise sealing and long-term durability.

Glass Edging

After cutting, the glass edges are ground and polished in a process known as glass edging. This step improves safety and aesthetics and, more importantly, prepares the glass for reliable sealing. Removing sharp edges and surface flaws helps maintain the structural integrity of the IGU throughout its service life.

Glass Washing and Drying

Once edged, the glass panes undergo thorough washing to remove dust, residues, and contaminants. Clean glass surfaces are essential for proper adhesion of sealants. Following washing, the panes must be completely dried to prevent moisture from becoming trapped inside the insulating glass unit.

Spacer Assembly

Spacers are installed to maintain a consistent gap between the panes of glass. The spacer’s material and dimensions influence the insulating performance of the IGU by controlling cavity width and supporting gas retention. Proper spacer selection contributes significantly to the overall thermal efficiency of the unit.

Gas Filling

Before sealing, the cavity between the glass panes is filled with an insulating gas, typically argon or krypton. This step is critical, as gas filling significantly improves the thermal performance of the IGU compared to air-filled units.

The gas fill rate must be precise, as insufficient gas concentration reduces insulating performance. Verifying correct gas filling also confirms that the gas press and sealing process are functioning as intended and according to insulating glass standards.

Understanding the Role of Machinery in Insulating Glass Assembly

Automated machinery plays a central role in IGU production. Automated systems ensure consistent spacing between panes, accurate application of sealants, and precise alignment during pressing. By reducing manual variation, automation improves efficiency and helps manufacturers achieve consistent quality at scale.

Overview of Cutting, Edging, Washing, and Sealing Processes

Precision Cutting and Edging Techniques

The combination of precise cutting and controlled edging ensures correct dimensions and smooth, safe edges, which are essential for accurate assembly and long-term sealing performance.

Advanced Washing and Drying Systems

Modern washing systems use specialized detergents and high-pressure water jets to clean glass surfaces thoroughly. Drying is typically performed using heated air to ensure that no moisture remains prior to assembly.

Gas Filling for Enhanced Insulation

The introduction of insulating gas into the cavity reduces heat transfer through the unit and supports low U-values in finished IGUs. Read our article How to Test for Argon Gas in Windows: Ensuring Quality in Insulated Glass.

Sealing for Insulation

A primary and secondary sealant are applied around the perimeter of the glass panes, enclosing the spacer. These sealants maintain gas retention, structural stability, and resistance to environmental exposure over time.

The Role of Add-Ons in Insulating Glass Production and Quality Control

Additional features in IGU production may include special coatings, additional glass layers, or specific gas fills. These add-ons enhance performance in terms of energy efficiency, sound insulation, and UV protection, depending on the application requirements.Read our article Visible vs. Invisible IGU Defects: Why Visual Inspection Alone Is Not Enough.

The Importance of Sparklike Insulating Gas Measurement Devices

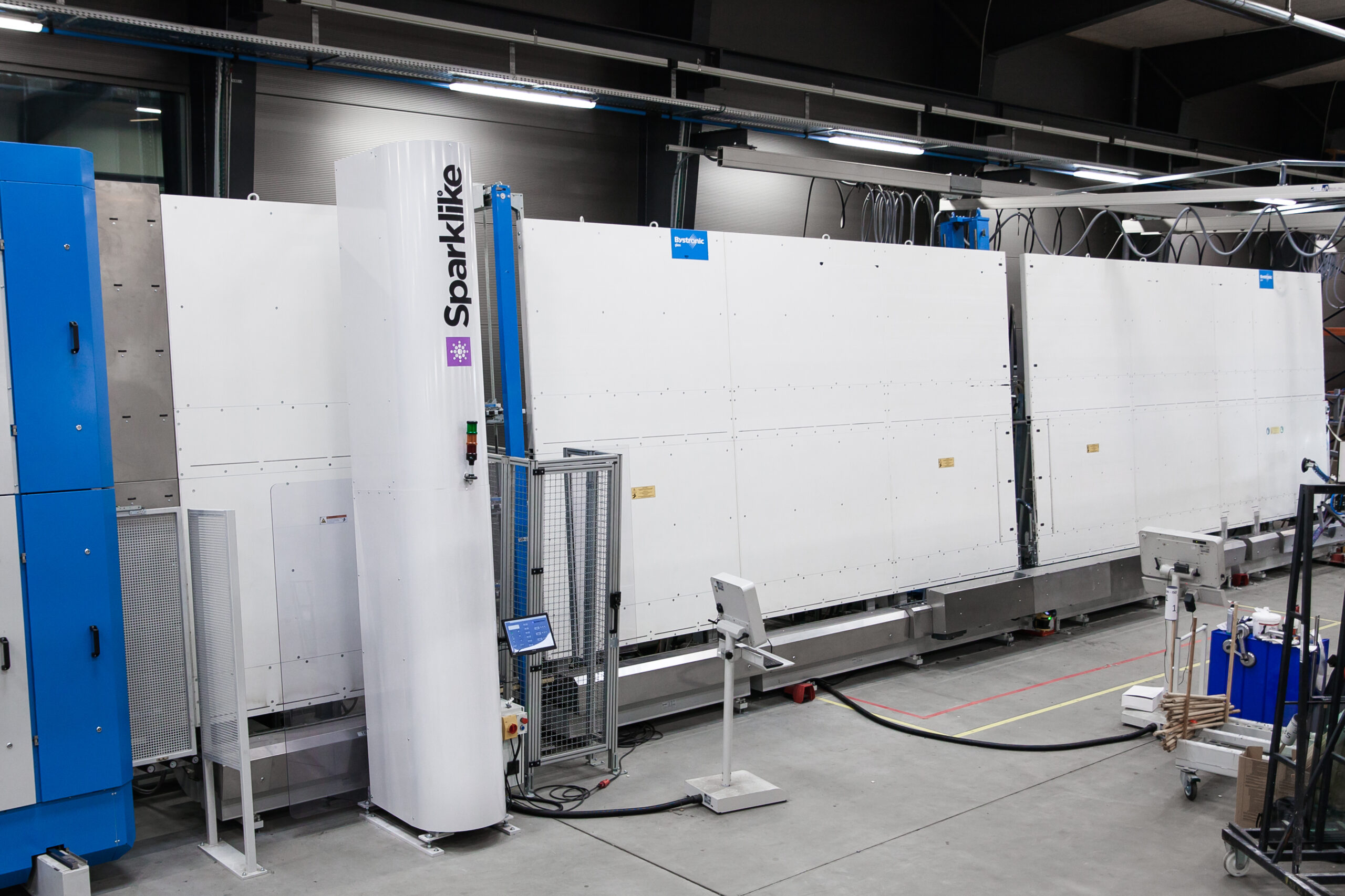

Quality control is a critical part of insulating glass manufacturing. Sparklike’s non-invasive gas measurement devices enable manufacturers to verify insulating gas fill levels without damaging the IGU.

Accurate gas measurement:

- provides evidence that gas filling and sealing processes work correctly

- confirms compliance with specifications

- supports thermal performance targets

Sparklike devices:

- Sparklike Handheld™ – for double glazed insulating glass units

- Sparklike Laser Portable™ – for double and triple glazed insulating glass units with coatings and lamination

- Sparklike Laser Integrated™ insulating gas measurement station integrated to the IG-line. For double and triple glazed insulating glass units with coatings and lamination.

These solutions improve quality assurance while preserving the integrity of the finished product.

Conclusion

The manufacturing of insulating glass units is a sophisticated process that depends on precision, technology, and effective quality control at every stage. From material preparation to sealing and final verification, each step contributes to the performance and reliability of the IGU.

By integrating accurate insulating gas measurement into production, manufacturers can strengthen quality control, ensure consistent performance, and deliver insulating glass units that meet modern energy efficiency and durability expectations.