Sparklike and our originators have been able to establish ourselves as the world industry leader in gas fill measurement which impacts gas press and its filling accuracy. Sparklike non-invasive gas measurement technology is, in fact, the de facto industry standard today. We are proud to say that Sparklike has successfully penetrated the world market with our niche technology in a typical application where market demand and technology development have successfully joined hands. Now we are happy to present the automated gas fill measurement – Sparklike Laser Integrated™.

As this year marks the 20th anniversary of Sparklike we decided to take you all for a closer look behind the scenes of the company. In this fourth article, of the Sparklike anniversary series we discuss what the future holds in terms of gas fill measurement. Sparklike intends to follow up our current products Sparklike Handheld™ and Sparklike Laser™ with new product developments in line with market needs and the development of glass, coating and IGU technology. All Sparklike devices are designed and assembled at Sparklike in Helsinki, Finland. Before customer delivery, each device is quality-controlled and calibrated by our Sparklike specialists.

In our first article of the anniversary series, we described the advantages of gas fill for thermal performance and the developments in gas fill measurement while the second article discussed the applied research and the partnering entrepreneurs behind Sparklike. The third article of the series detailed the breakthrough technology used in the manufacturing of our non-destructive insulating gas analyzers.

The new Sparklike Laser Integrated™ measuring station

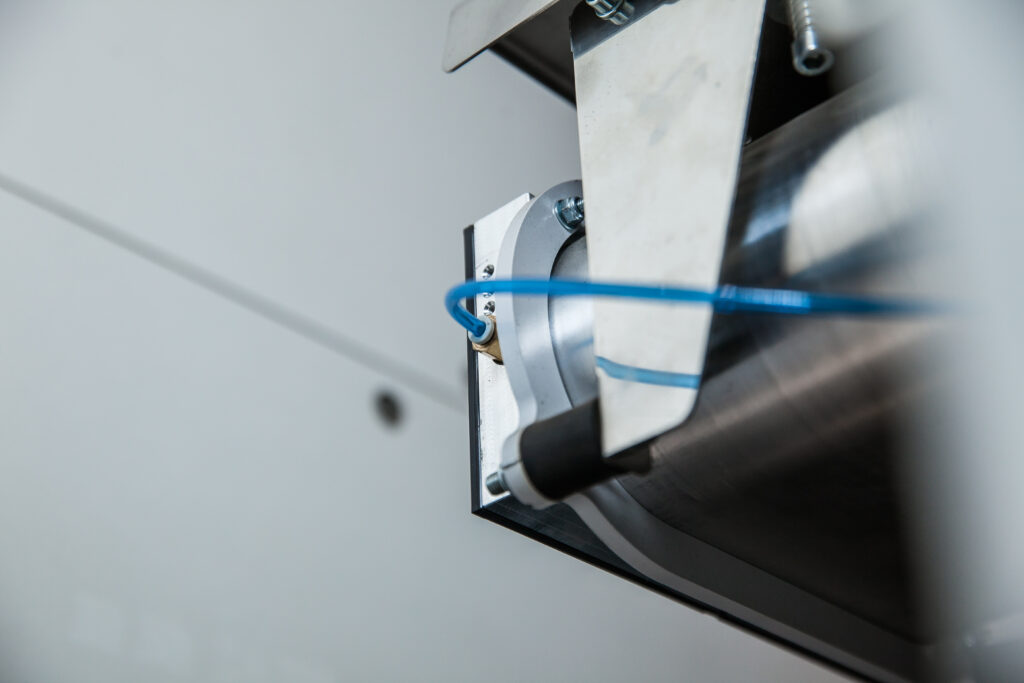

The Sparklike Laser technology was originally launched to market in Fall 2014. The latest development in the Sparklike laser technology portfolio is the Sparklike Laser Integrated™. In Fall 2018 Sparklike introduced Sparklike Online™, now called Sparklike Laser Integrated™ , the non-destructive measurement station. Integrated directly to any IG-line it provides information on the gas fill right after the filling process. The Sparklike Laser Integrated™’s dimensions and speed are compatible with all kinds of IG-lines and the level of integration can be adapted based on the customer’s needs and insulating glass line requirements.

Fully automatic – the IGU just need to stop for measurement

Insulating glass units are measured automatically after the gas press and all the results are recorded to its memory and can, therefore, be sent back to the IG-line or its ERP-system. Based on this information it is possible to react immediately to a possible gas fill flaw as well as help optimize the gas fill process. This ultimately enables the saving of both utilized gas as well as time saved in the gas press.

Benefits of line-integrated measurement

- Easy installation to flat floor by the IG-line and not touching the line, only the IGU

- Required by the market – concluding the quality control procedure

- Product traceability

- Gas press adjustment – saving both time and gas

- Sales argument for IGU-sales

- No costs or errors by man-made control

- Related to the increasing quality consciousness and measurements in the building

The new Sparklike Laser Integrated™ measuring station shares the TDLAS measurement technology form the Laser product family with a proven performance record of over 150 units delivered globally.

Outstanding quality at pair with advanced product expectations

The non-destructive testing methods developed by Sparklike makes it possible to measure even the most complex insulating glass structures. In other words, the latest advancements in measuring technology solve the issues attached to traditional, invasive methods, which were and still are being used to test insulating glass gas concentration. Since the laser-based technology is capable of measuring both non-destructively, as well as through coatings and laminations, the technology allows testing of complicated structures, such as energy-efficient triple glazed units. As laser technology measures the level of oxygen non-invasively, it can, in the same way, measure the percentage of any gas. This brings the level of quality assurance of these high performing glazing units at pair with advanced product expectations.

Would you like to know more about Sparklike Laser Integrated™?

ADDITIONAL INFORMATION ON THE SPARKLIKE PRODUCT RANGE:

- Sparklike Handheld™ – Portable and battery-operated gas fill measurement of standard double glazed IGUs

- Sparklike Laser™ – Measuring IG gas fill of triple and double glazed units

- Sparklike Laser Integrated™ – Line integrated measurement