Summary – Argon-Filled Units: Why Fill Rate Matters

- Performance Depends on Fill Rate: The thermal insulation of IGUs is directly linked to argon concentration. A drop in gas levels can worsen U-values by up to 30%, leading to higher energy consumption.

- Long-Term Efficiency at Risk: Gas loss is invisible but reduces insulation over time, increasing heating/cooling costs if not controlled.

- Cost vs. Benefit: Argon adds minimal production cost but delivers significant efficiency gains, only if quality filling and sealants are ensured.

- Quality Control is Essential: Studies (e.g., AkzoNobel) confirm that >90% argon fill is critical. Non-destructive tools like Sparklike Handheld™, Laser Portable™, and Laser Integrated™ help manufacturers verify and maintain proper gas levels.

- Conclusion: Reliable insulation performance requires not just filling IGUs with gas, but verifying and maintaining the correct gas fill rate through quality control.

Insulating glass units (IGUs) are a cornerstone of energy-efficient buildings, delivering thermal insulation, noise reduction, and long-term comfort. Many modern IGUs rely on argon-filled units to achieve the required insulation performance.

However, a critical factor is often overlooked in quality control: the exact gas fill rate inside the IGU cavity.

While some manufacturers focus only on the presence of argon or krypton, Sparklike aims to educate the industry on why the precise fill rate in argon-filled insulating glass units matters and how insufficient gas levels directly impact U-value, energy efficiency, and long-term performance.

Why Gas Fill Rate Matters in Argon-Filled Units

1. Thermal Performance and Energy Savings

The thermal insulation performance of an IGU is directly linked to its gas fill rate. Low-E argon-filled units significantly outperform air-filled IGUs, but only when the gas concentration is sufficiently high.

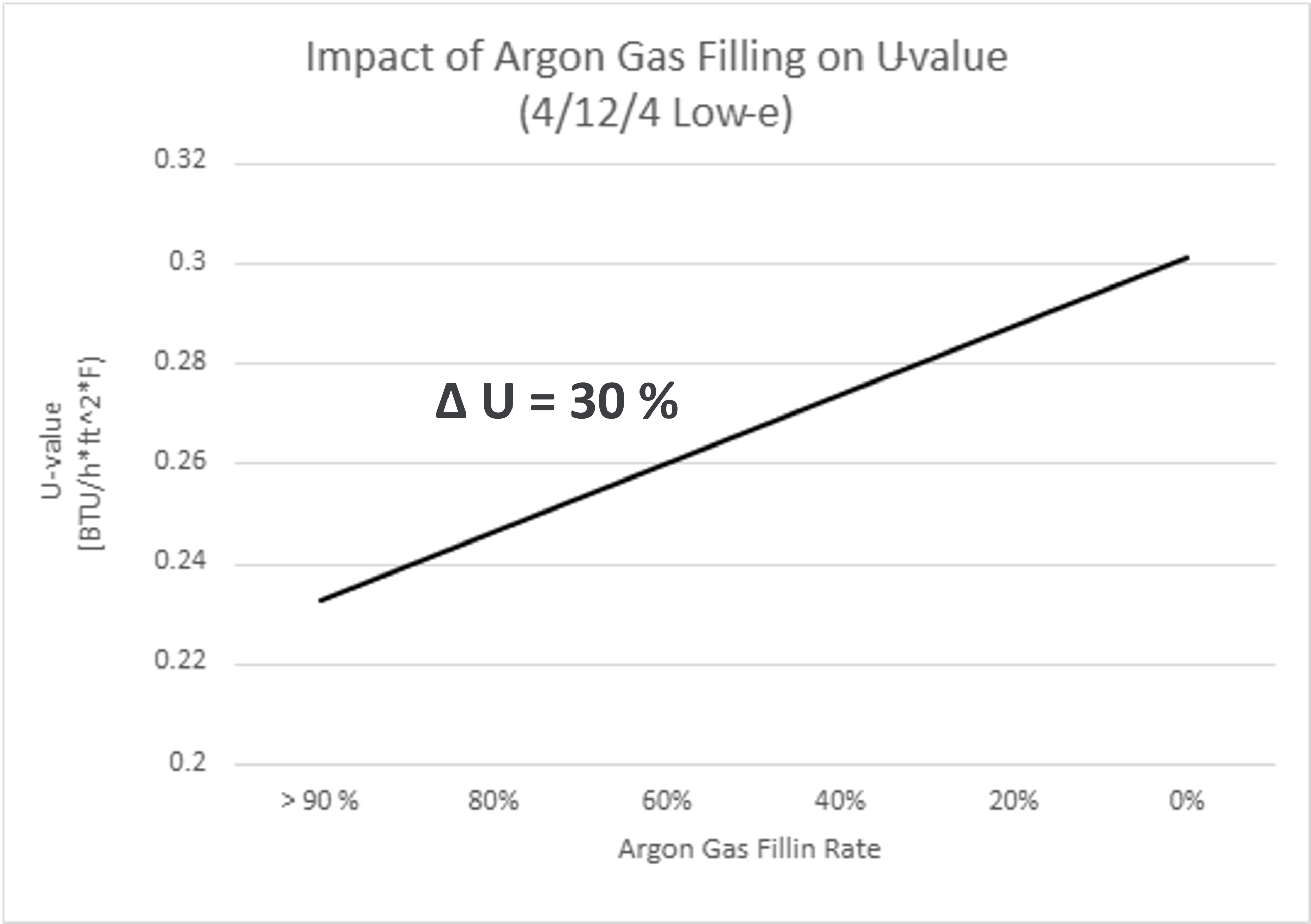

Studies have shown that increasing the argon fill rate improves the U-value (Ug-value) of the unit, a critical metric followed by window manufacturers, specifiers, and regulators.

According to research, a drop in argon concentration can increase the Ug-value by approximately 0.07 BTU/(h·ft²·°F), leading to measurable increases in energy consumption and reduced insulation performance.

2. Long-Term Efficiency of Argon-Filled IGUs

Gas loss in sealed insulating glass units is not visible to the naked eye, which makes ongoing quality assurance essential.

As argon levels decline over time:

- Thermal insulation performance deteriorates

- Heating and cooling demand increases

- The actual U-value may deviate from the specified performance

Research highlights that even relatively small reductions in gas concentration can have measurable impacts on long-term energy efficiency, underlining the importance of consistent gas measurement during production and quality control.

How to detect Gas Leakage in Insulating Glass Units with Sparklike devices.

3. Cost vs. Benefit of Proper Gas Filling

Filling IGUs with argon involves minimal additional material cost compared to air-filled units, yet the performance benefit is substantial. However, these benefits only persist if:

- High-quality sealants are used

- Manufacturing processes are well controlled

- Gas fill rates are measured, not assumed

Without proper measurement, manufacturers cannot verify whether argon-filled units actually meet their intended performance specifications.

Insights From Studies: Argon Fill Rate and U-Value

Research conducted by AkzoNobel clearly demonstrates the relationship between argon concentration and thermal performance.

Key findings include:

- IGUs with argon fill rates above 90% achieve significantly lower U-values

- Units with 60% argon or less show a clear decline in insulation performance

- Without sufficient gas, the U-value can be up to 30% worse than the specified value

This data highlights a critical point: argon-filled units without verified fill rates cannot be assumed to perform as designed.

The Role of Quality Control in IGU Manufacturing

For manufacturers, ensuring reliable performance means verifying not only the presence of argon, but that the gas concentration meets the optimal percentage required for peak performance.

Effective quality control for argon-filled units includes:

- Consistent gas fill verification during production

- Detection of gas loss caused by seal integrity issues

- Documentation of gas concentration for compliance and traceability

Sparklike devices enable non-destructive measurement of gas fill rates, allowing manufacturers to verify insulation performance without damaging the IGU.

Sparklike devices to measure gas fill of insulating glass units

- Sparklike Handheld™ – for double glazed insulating glass units

- Sparklike Laser Portable™ – for double and triple glazed insulating glass units with coatings and lamination

- Sparklike Laser Integrated™ insulating gas measurement station integrated to the IG-line – for double and triple glazed insulating glass units with coatings and lamination.

These solutions support reliable insulation performance by making gas fill rate measurable, repeatable, and verifiable.

Conclusion: Reliable Performance Requires Verified Gas Fill Rates

Argon-filled units play a vital role in achieving today’s insulation and energy efficiency requirements. However, argon only delivers its full benefit when the gas fill rate is high enough and verified.

The AkzoNobel study confirms what many manufacturers observe in practice: insufficient argon concentration leads directly to poorer U-values and reduced insulation performance. For this reason, measuring gas fill rate is a critical step in producing reliable, compliant, and high-quality IGUs.

Contact Sparklike for more information and support on measuring argon concentration in IGUs.

Source

D. Lange. 2012. Energy Saving Without Noble Gas Filling? AkzoNobel.