In China, insulating glass unit (IGU) performance is defined and verified through national standards. One of the main references for IGU manufacturing and testing is Chinese Insulating Glass Standard GB/T 11944.

GB/T 11944 describes technical requirements for IGU structure, durability, and performance verification. It also includes guidance related to gas concentration measurement, which is used to confirm whether gas-filled insulating glass units meet expected thermal performance targets.

This article summarises how GB/T 11944 relates to gas concentration verification and why it matters for IGU manufacturers supplying the Chinese market or working with Chinese partners.

Related reading

- Standards and Regulations in Insulating Gas Measurement,

- National Construction Code (NCC) in Australia

- ENERGY STAR® 7.0 requirement in the US.

What Is Chinese Insulating Glass Standard GB/T 11944

GB/T 11944 is the national standard that defines technical requirements for insulating glass units (IGUs) in China. It provides guidance on IGU structure, manufacturing quality, performance testing, and verification methods used within the Chinese construction and glazing industry.

The standard covers multiple aspects of insulating glass performance, including dimensional tolerances, durability, sealing quality, and thermal behavior. Its purpose is to ensure that IGUs placed on the market meet defined quality and performance expectations under Chinese building conditions.

For gas-filled insulating glass units, GB/T 11944 also addresses how gas concentration is verified as part of performance validation. This links gas content directly to thermal performance requirements and supports consistent quality control across production lines.

Understanding the scope of GB/T 11944 is therefore important for manufacturers supplying the Chinese market, as well as for international companies cooperating with Chinese partners or exporting IGUs to China.

Why Gas Concentration Matters for IGU Performance

Insulating glass units consist of two or more panes of glass separated by a sealed cavity. Compared to single pane glazing, this structure improves thermal insulation and acoustic performance.

The gas contained within the cavity, most commonly argon or krypton, contributes directly to these performance improvements. By reducing heat transfer through the glazing, insulating gases support lower U-values and more stable indoor conditions.

To achieve these results consistently, the gas must be filled at the specified concentration and retained over time. GB/T 11944 addresses this requirement by defining how gas concentration is measured and verified, supporting consistent IGU quality across Chinese production lines.

Gas Concentration Measurement Requirements in GB/T 11944

GB/T 11944 defines requirements for verifying the inert gas concentration in gas-filled insulating glass units as part of product performance and quality assessment.

For gas-filled IGUs, the standard specifies that gas concentration shall bemeasured using defined test methods, with requirements covering both initial gas content and gas retention after durability testing. The purpose of these measurements is to confirm that gas-filled units meet declared performance expectations and maintain their insulating properties over time.

According to the standard, the inert gas concentration in gas-filled insulating glass units shall meet the following criteria:

- Initial gas content shall not be lower than 85% (v/v)

- After gas-sealing durability testing, the average gas content shall remain at or above 85% (v/v)

- The minimum measured gas content shall not fall below 80% (v/v)

Gas concentration testing is carried out under controlled environmental conditions. The reference test method for inert gas measurement is defined in GB/T 38214, which is cited by GB/T 11944 as the arbitration method for determining inert gas content. For multi-cavity insulating glass units, gas concentration is measured separately for each cavity.

These measurement requirements ensure that gas-filled insulating glass units not only meet performance targets at the time of manufacture, but also demonstrate sufficient gas retention and sealing performance under defined durability conditions. Together, they support consistent quality control and comparability of IGU performance across Chinese production and certification processes

Who Needs to Follow GB/T 11944

For insulating glass manufacturers operating in China, GB/T 11944 functions as a core quality reference, supporting compliance with national performance expectations and market requirements.

For international companies, familiarity with GB/T 11944 is relevant when:

- Cooperating with Chinese IGU manufacturing partners

- Supplying components or systems for the Chinese market

- Aligning quality control processes across regions

A shared understanding of the standard supports clearer technical communication, smoother certification processes, and more consistent product quality.

Architects, specifiers, and builders also benefit from insight into GB/T 11944. Selecting insulating glass units manufactured in line with the standard supports predictable thermal performance, reduced noise transmission, and long-term building comfort.

Measurement Technologies: Laboratory Sampling vs Non-Invasive Methods

As sustainability and energy efficiency continue to influence construction practices, standards such as GB/T 11944 are expected to evolve alongside measurement technologies and quality control approaches.

GB/T 11944 defines gas concentration requirements while remaining neutral with respect to measurement technology. In practice, laboratory-based test methods are commonly used as reference or arbitration methods for gas concentration verification.

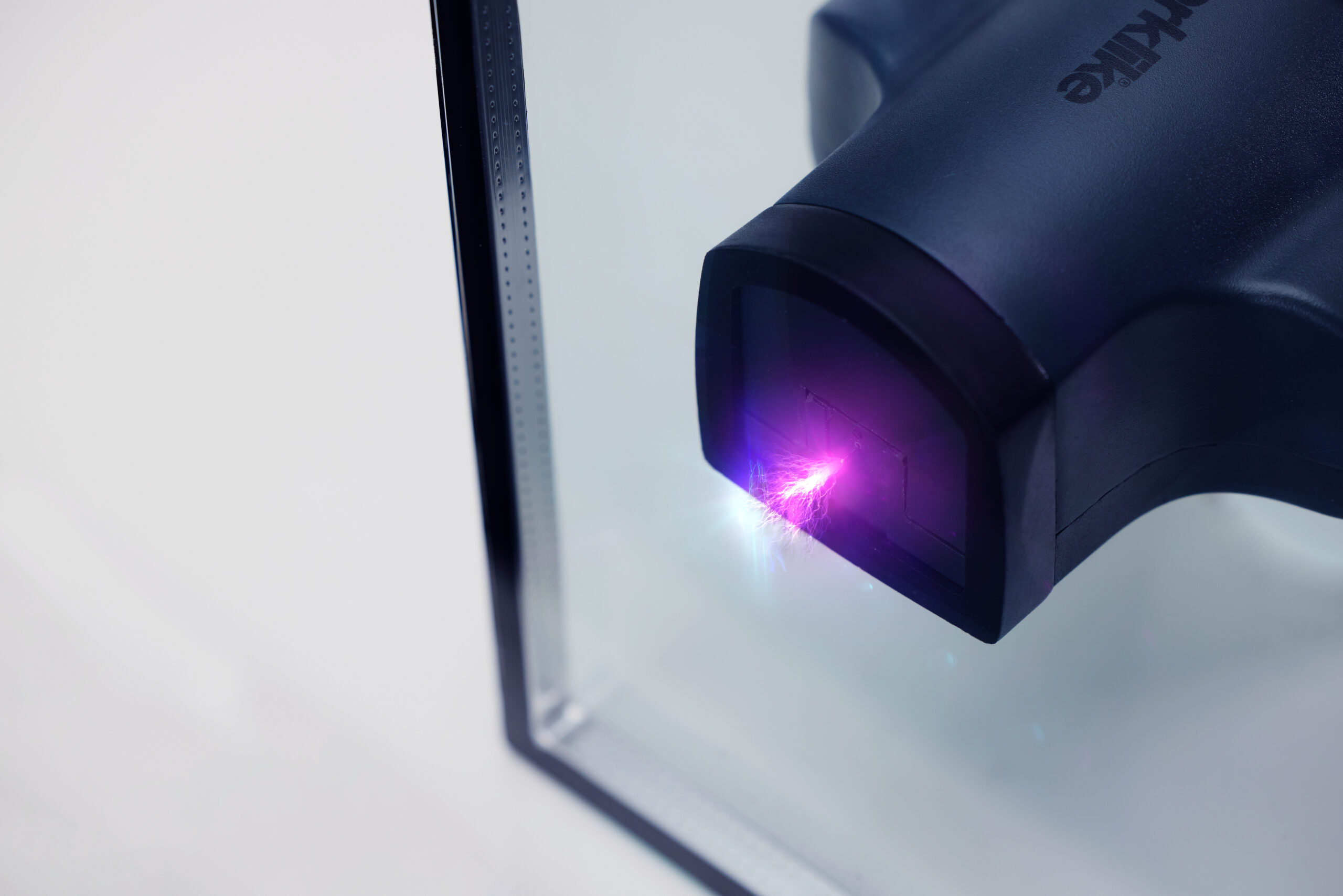

At the same time, non-invasive gas concentration measurement technologies enable additional ways to verify IGU performance without damaging the glass. Laser-based analyzers, for example, allow gas concentration to be measured during production, on-site commissioning, or in-service inspections.

These approaches complement laboratory testing by supporting faster feedback, repeated verification, and broader quality control coverage. Together, they contribute to long-term performance monitoring and reliability in gas-filled insulating glass units.

Conclusion

The Chinese insulating glass standard GB/T 11944 provides a structured framework for verifying gas concentration in gas-filled insulating glass units. While its requirements are specific to the Chinese market, the underlying objective — consistent performance, durability, and quality verification — is shared globally.

By understanding and applying the principles outlined in GB/T 11944, manufacturers and partners can strengthen quality control practices, align with regional expectations, and support the delivery of insulating glass units with predictable long-term performance.