Insulating glass manufacturers want to assure that their production is controlled, and that they deliver the best quality products to customers. The quality operators take regular measurement to check the insulating gas concentration. This means that the operators need to trust the reading. Therefore, Sparklike devices should be calibrated annually ensure correct measurement of insulating gas concentration and product quality. To make the maintenance of Sparklike devices™ as easy and as convenient as possible, Sparklike offers its customers globally an all-inclusive calibration and maintenance service, also known as Sparklike CARE™.

QUALITY MEASUREMENT WITH ANNUAL SPARKLIKE SERVICE

Sparklike CARE™ means that your Sparklike device™ is controlled and serviced annually by Sparklike Certified Professionals. This annual service agreement options guarantees, that you receive an all-inclusive service to your device. Starting with reminding the device owner of the approaching calibration time and ending with the delivery of your newly calibrated device that has the wear and tear parts replaced with latest updates.

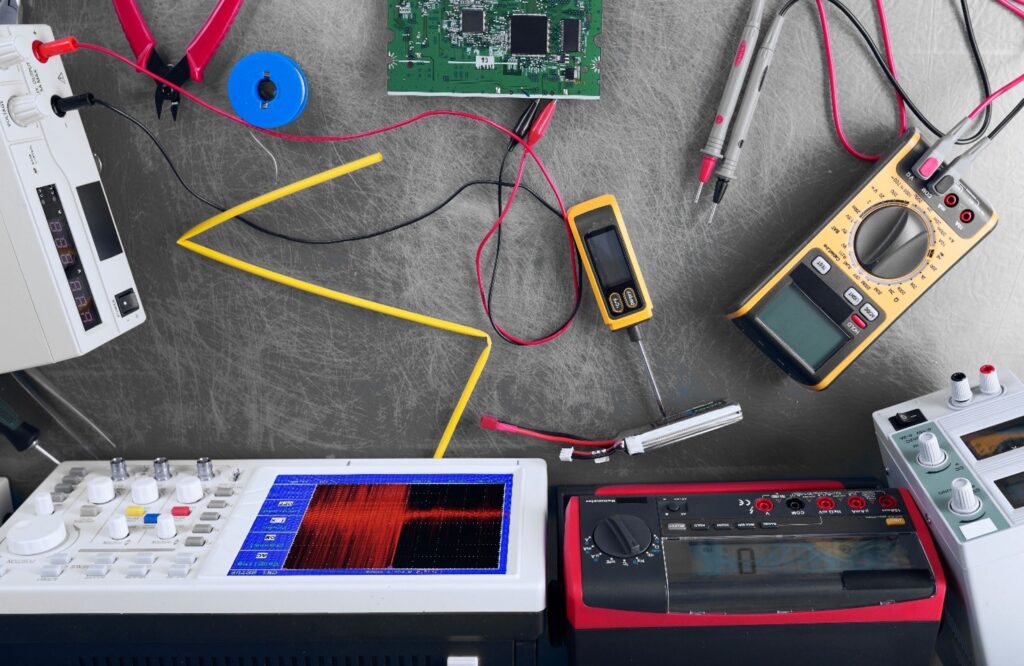

When device arrives for the annual maintenance, Sparklike Certified Professionals start the maintenance process by first testing the device’s operations. As a general procedure, this means checking the parts for wear and tear defects. The Sparklike CARE™ annual service agreement includes replacement of most common wear and tear parts. After testing the device’s operations, and replacing of the necessary wear and tear elements, Sparklike Engineers will perform an inspection and adjustment of optics. In case of regular calibration work, Sparklike Engineers quote the customer for a permission to proceed, if extra repair to the device is needed.

During the next phase in the Sparklike quality assurance protocol, the Sparklike devices are calibrated by checking the reference measurements. If any variances occur, necessary actions will be taken to fine tune the device.

Fine tuning in itself means analyzing the reference measurements and adjusting the insulating gas concentration readings throughout the whole measuring range. At this stage, several hundreds of measurements are being conducted using different references and methods to secure the reading accuracy.

Eventually the calibrated device is returned to the operator together with the calibration certificate. To make things as easy as possible for their customers, Sparklike keeps a record of all calibrated analyzers. A reminder email is being sent to the customer to remind of the approaching calibration. This way the customer can rest easy for a year, until it’s time to calibrate the device again.

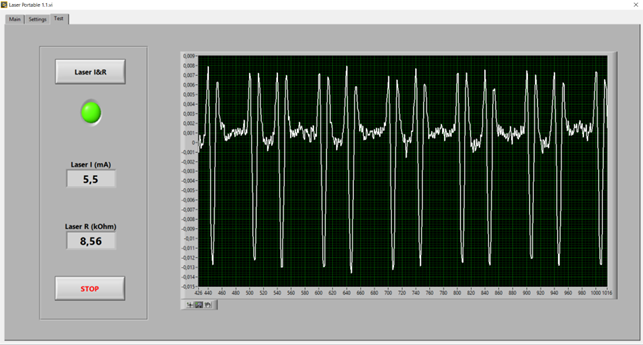

Although, Sparklike is continuously developing new methods to analyze insulating glass gas content, it is committed to continuously improving its existing devices. Thus, during the next phase of the quality assurance protocol, Sparklike Certified Specialists look to improve the usability of the Sparklike devices. Therefore, they run new software updates for the Software by Sparklike. These software updates allow the access to the latest features that can further improve the accuracy of the reading. This update is always part of the calibration process.

In the final stage of the quality assurance protocol, a set of quality testing and verification for the device is conducted. Finally, the newly serviced device will be packed and returned to the customer. In order to provide an all-inclusive service to its customers, Sparklike can arrange a pick-up and return of the device, if needed.